Industrial Freeze Dryer

Industrial freeze dryer, as an indispensable high-end equipment in the fields of modern biopharmaceutical, food processing, material science and so on, is the key technical means to realize low-temperature dehydration and drying of materials. It makes the moisture in the pre-frozen material sublimate directly from solid state to gas state without going through liquid state by utilizing the principle of sublimation in a highly vacuum environment, so as to achieve the purpose of high-efficiency and non-destructive drying, and retain the original structure, activity and nutritional value of the material to the maximum extent.

We provide a full range of personalized customization services, according to the specific needs of customers, tailor-made freeze dryer size, capacity, material and special functional modules (such as CIP automatic cleaning, aseptic isolation device, etc.) to meet the needs of different industries and production scale.

Industrial Freeze Dryer Description

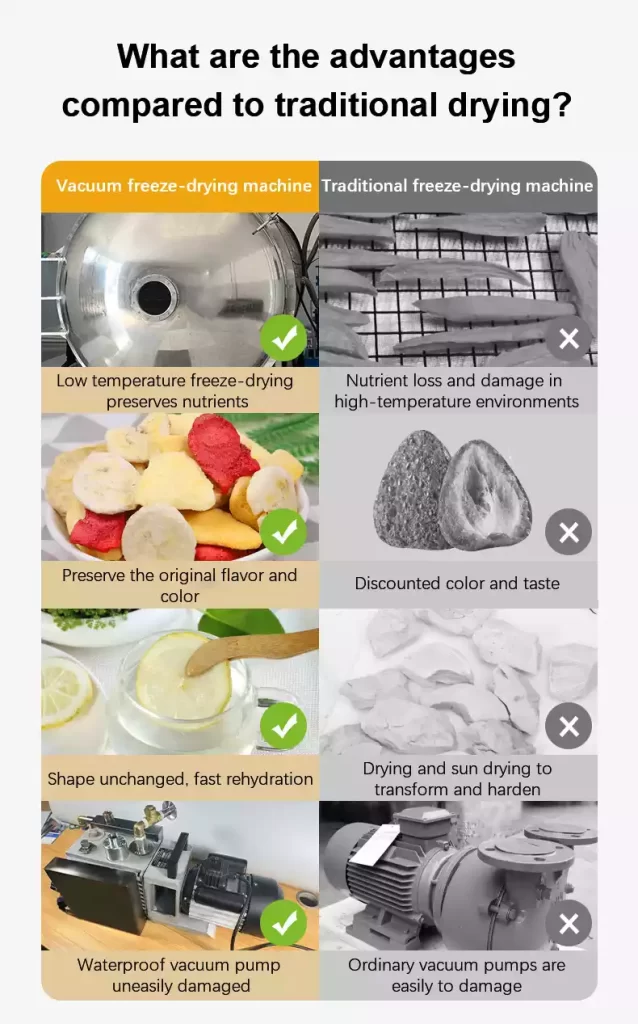

The vacuum freeze dryer lyophilizer machine is advanced drying equipment, vacuum freezing drying freezes the fresh material under low temperature, under the vacuum low temperature, heats it, makes the ice in the material turn into vapor directly by sublimation, and is collected by condensation. This method reaches fast drying, keeping the material's shape and nutrition to the maximum degree. They are widely used in medicine, beauty products, and other fields.

The working principle of this freeze vacuum dryer is that the machine removes the moisture in the pre-frozen material under the high vacuum state, it makes the moisture steamed under the Ice state and doesn't have to melt into water. This machine will pre-frozen the material and then create a high vacuum state to heat the material to dry with low temperature, which will best maintain the physical properties, and can keep long after drying, compared with other drying ways.

Industrial Freeze Dryer Benefits

1. Keep the shape of the material

2. Keep the nutrition, and flavor of the material

3. Crispy

4. Spongy and porous

5. Easy to solve in water and crush

6. Low moisture, easy to store

7. We can provide custom machines of different volumes based on your requirements.

Industrial Freeze Dryer working process

- Clean the fruit and tidy up

- Cut into flakes or blocks

- Place it flat on a material tray and then put it into the freeze-drying room

- Set up the freeze-drying process and control the operation with intelligent equipment

- Wait for the program to finish, and then take out the sealed package

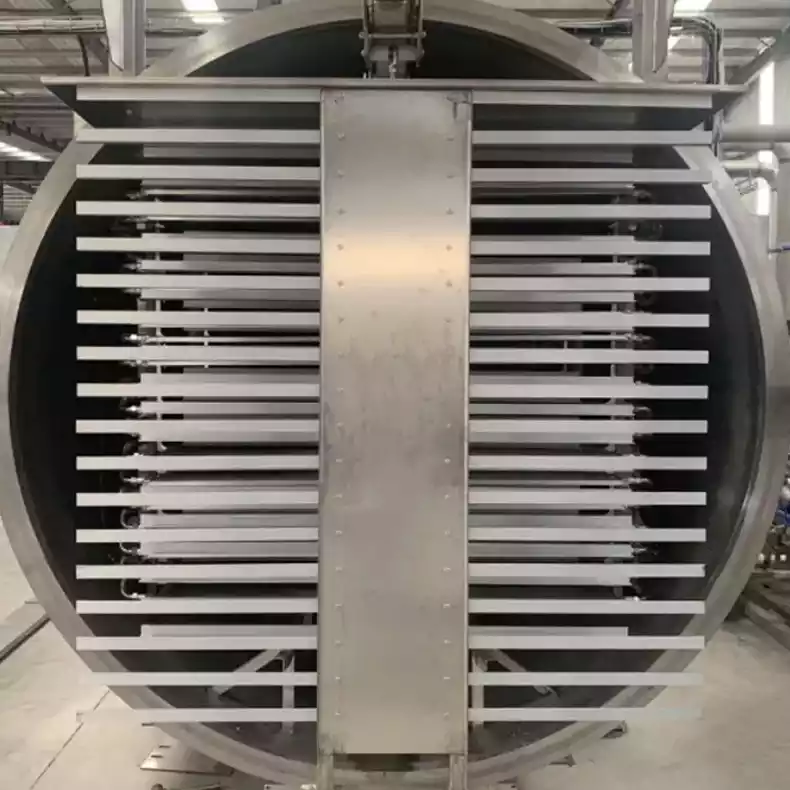

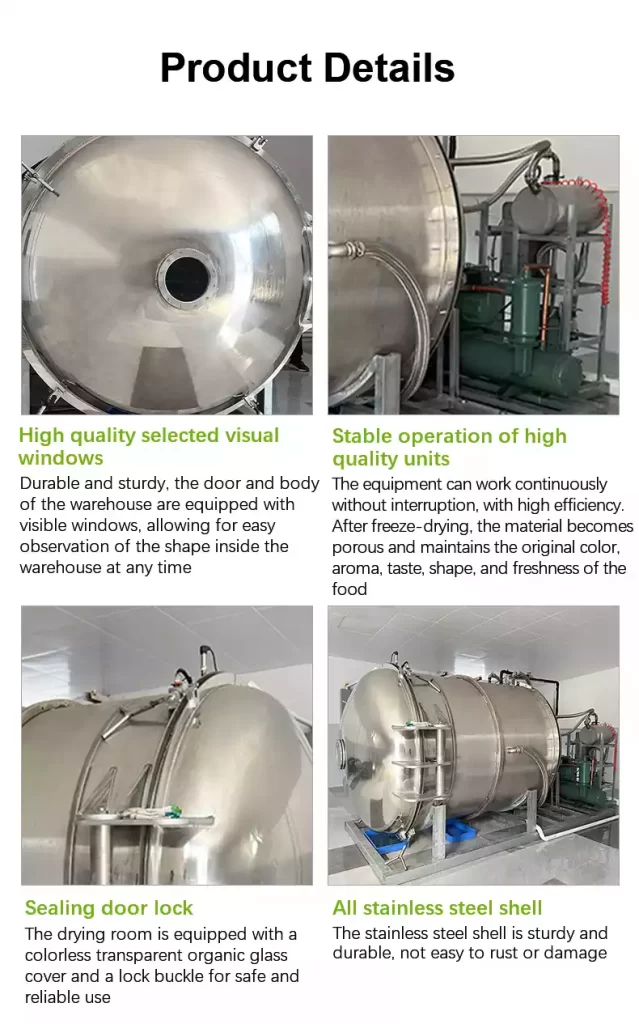

Industrial Freeze Dryer Details

Industrial Freeze Dryer Application

Medicine, beauty products, and other fields.

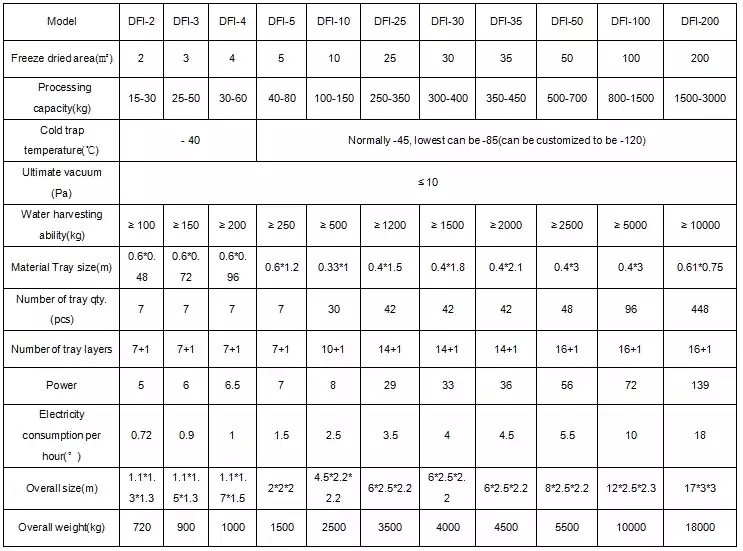

Industrial Freeze Dryer Specifications